Context: Enterprise SaaS tool for global hardware inventory and asset management

Role: Sr. Staff UX Manager · Team Lead

Timeline: Feb 2019 – Dec 2019

G.E. Digital

Designing MyTech: A scalable enterprise system for managing global devices and spend

MyTech was created to help GE manage thousands of devices across dozens of business units — each with unique hardware needs, budgets, and rules. As UX lead, I designed a unified B2B2C platform that streamlined data ingestion, permissions, approvals, SKU browsing, and procurement into a single, scalable system used around the world.

01

Understanding the challenge

Mapping the Scale and Complexity of Global Asset Management

Inconsistent Hardware Needs — Every new hire required a different mix of computers, phones, accessories, and permissions, making it difficult to track usage, budgets, and provisioning across business units.

Massive Inventory Footprint — GE managed thousands of devices across dozens of regions, each with unique rules for spend approval, ordering, and SKU visibility.

Fragmented Processes — Data ingestion, SKU mapping, budget workflows, and approvals were spread across disconnected systems without a unified interface.

No Single Source of Truth — Administrators struggled to understand what was available, who could order what, and how costs were distributed across teams and regions.

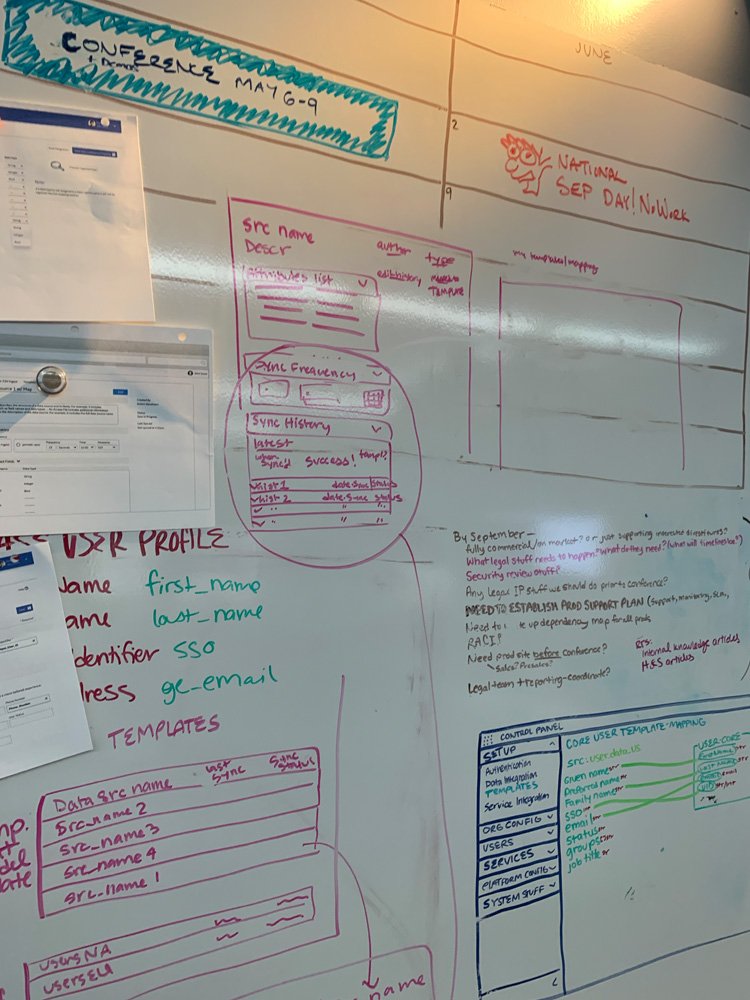

Early Wipeboard sessions front end user UI

Post It Note Affinity Mapping exercises

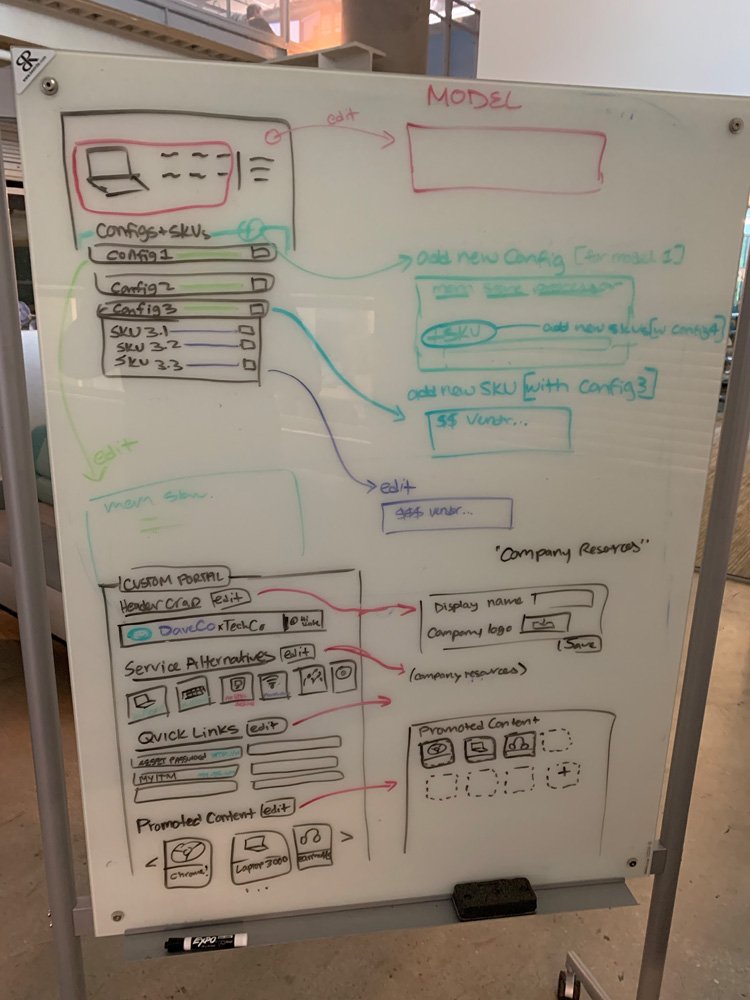

Mock Up UI feature updates

Understanding Data Ingestion

Product Details Wipeboarding

02

Structuring a scalable system

Designing the Foundation for Navigation, Permissions and Procurement

Information Architecture at Enterprise Scale — Built a left-rail navigation framework that supported category hierarchies, collapsible parent/child structures, and rapid expansion as features were added.

Data Ingestion & Mapping Logic — Designed the experience for uploading and parsing datasets via CSV and Elasticsearch, including SKU mapping, device categories, personnel associations, and ownership duration.

Role-Based Permissions Model — Created a flexible, rules-driven visibility system that controlled which users, regions, or business units could see or order specific SKUs.

Approval & Oversight Tools — Mapped workflows for overrides, spend approvals, exception handling, and multi-step administrative review.

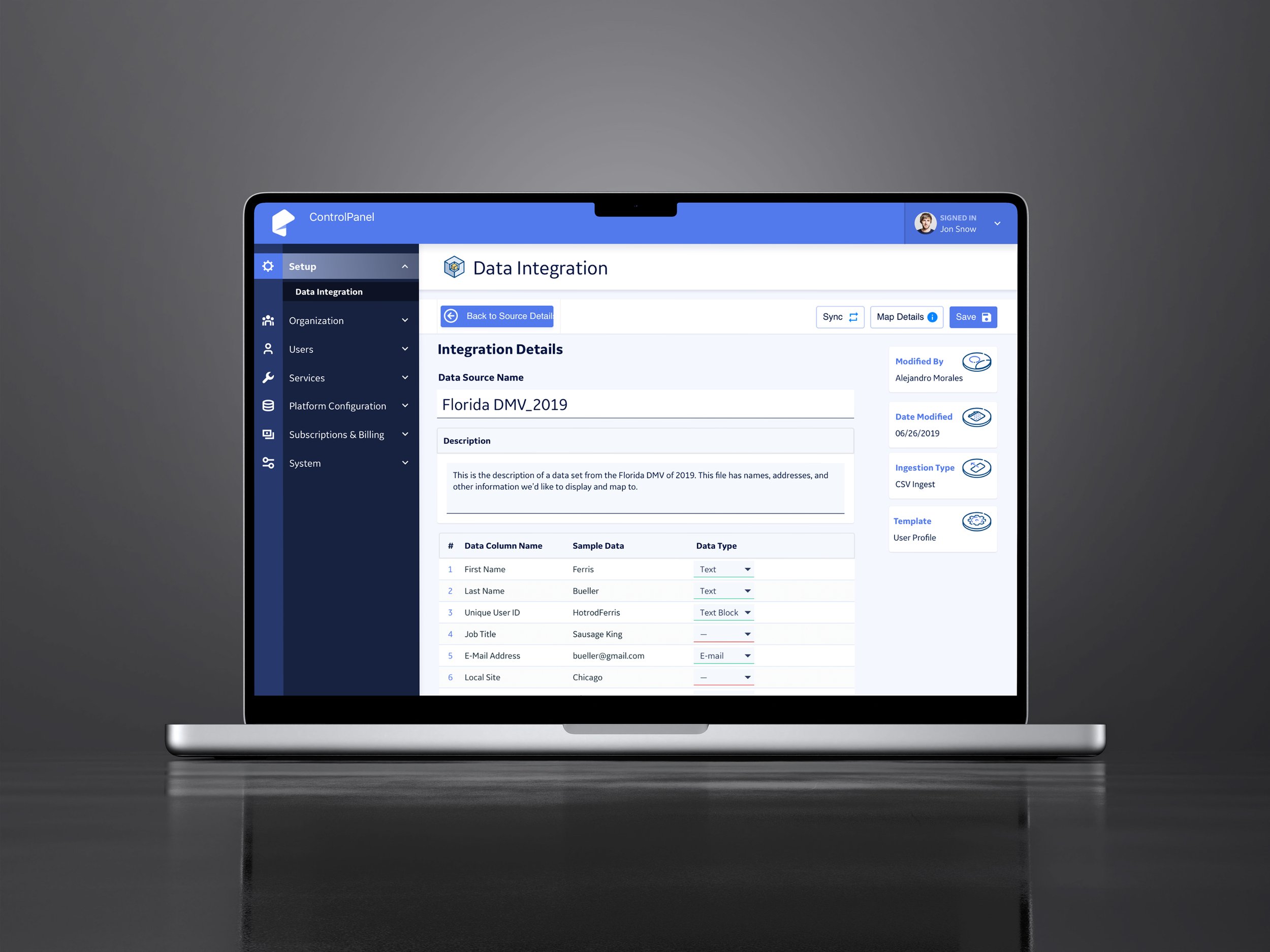

Simplifying Data Management

Businesses can upload their datasets via CSV or Elasticsearch. Our system accurately parses data to display SKU data, personnel information, and tracks asset ownership duration. Through this prototype walkthrough you can understand data ingestion, mapping, and template integration.

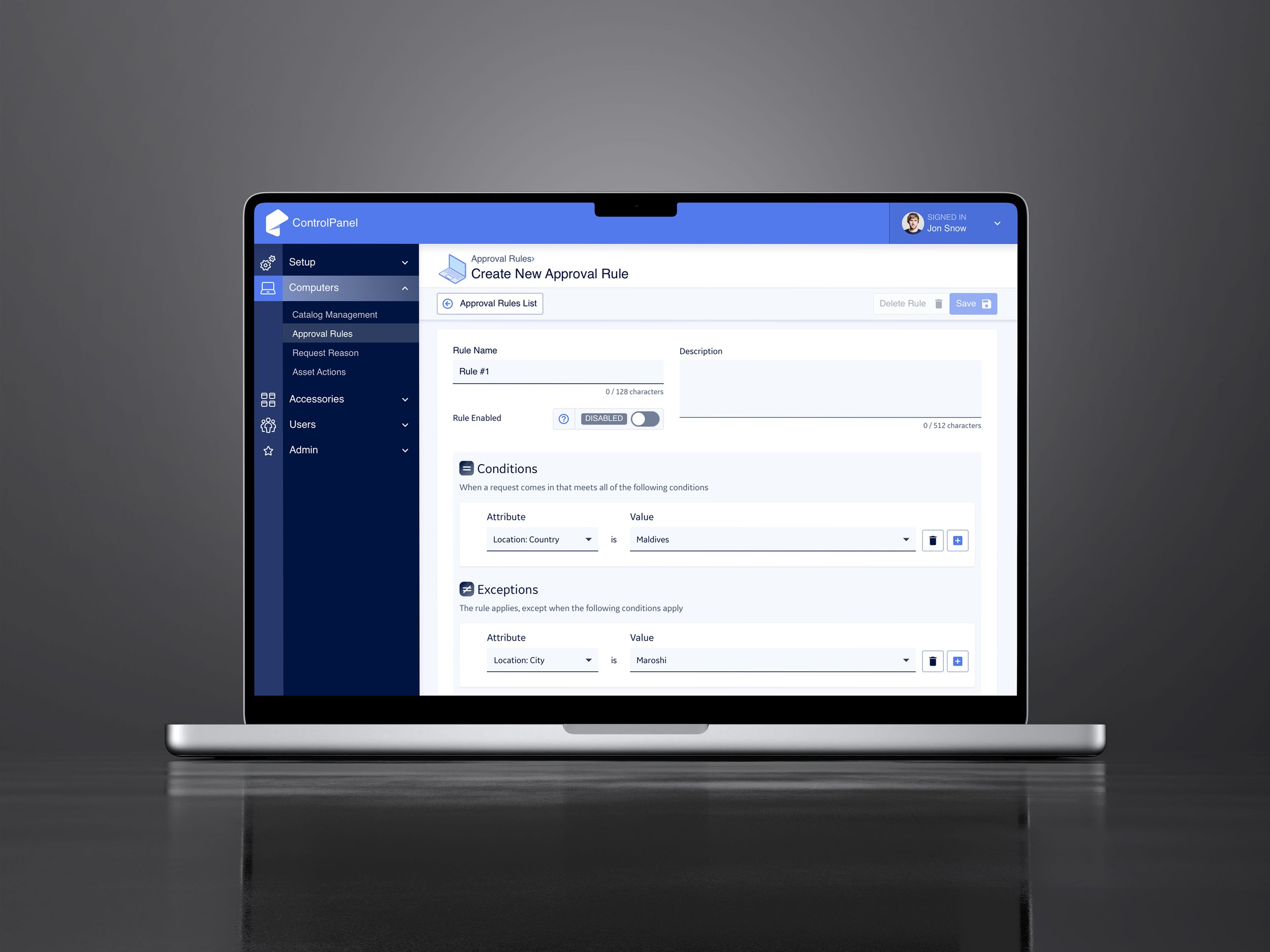

Approvals

Step by step admin UI to allow for overrides and approvals to work. tep admin UI to allow for overrides and approvals to work.

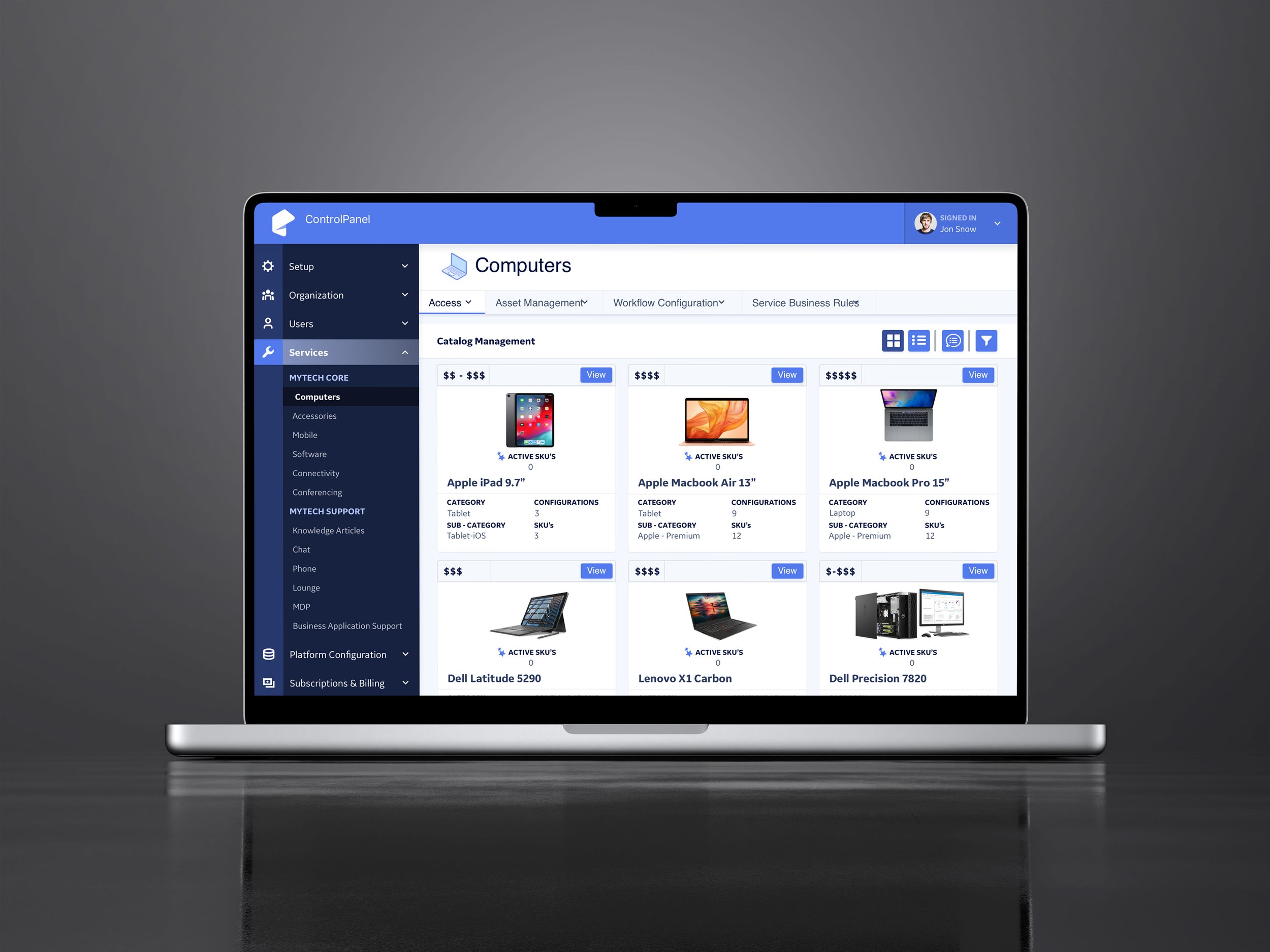

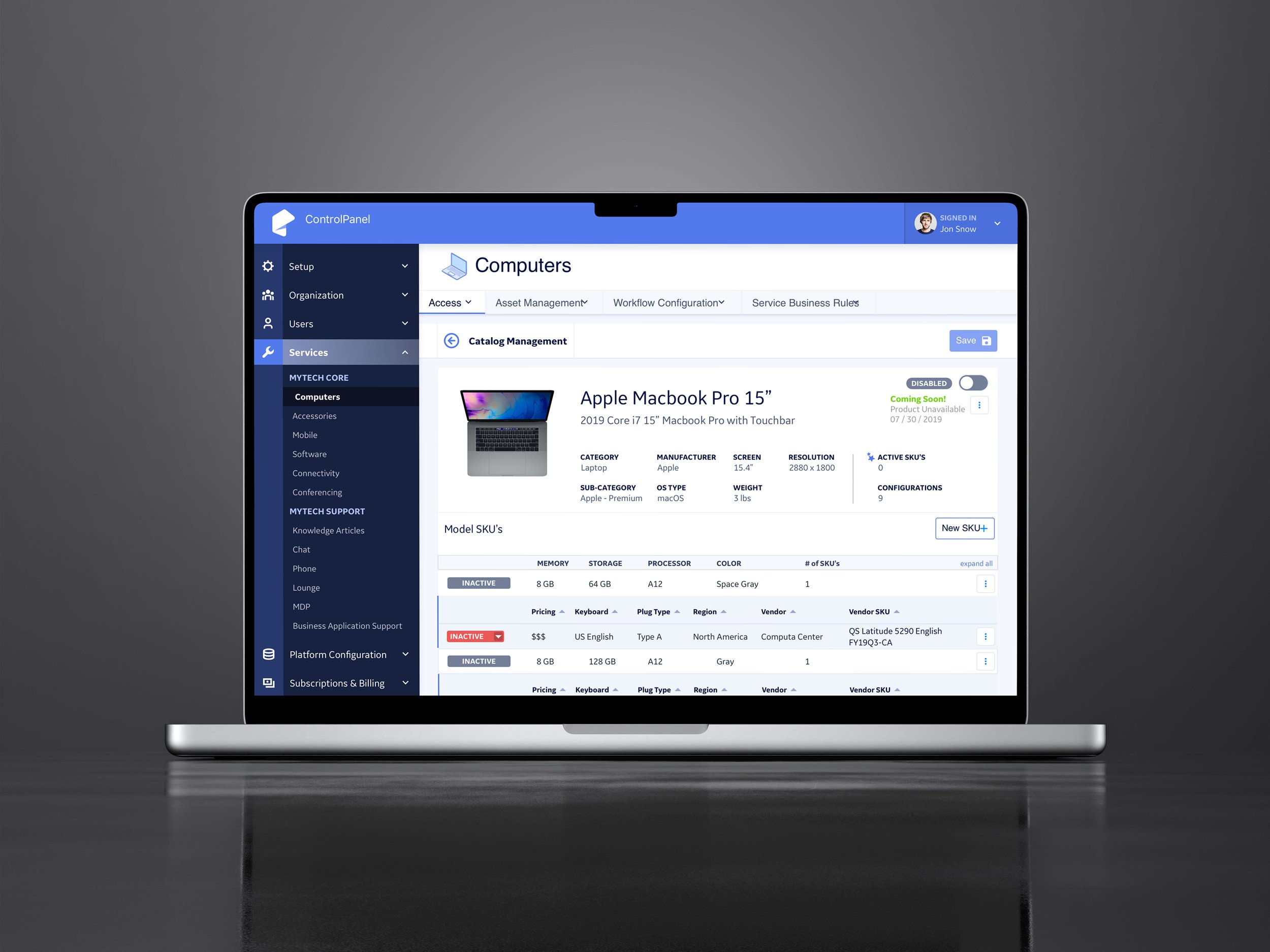

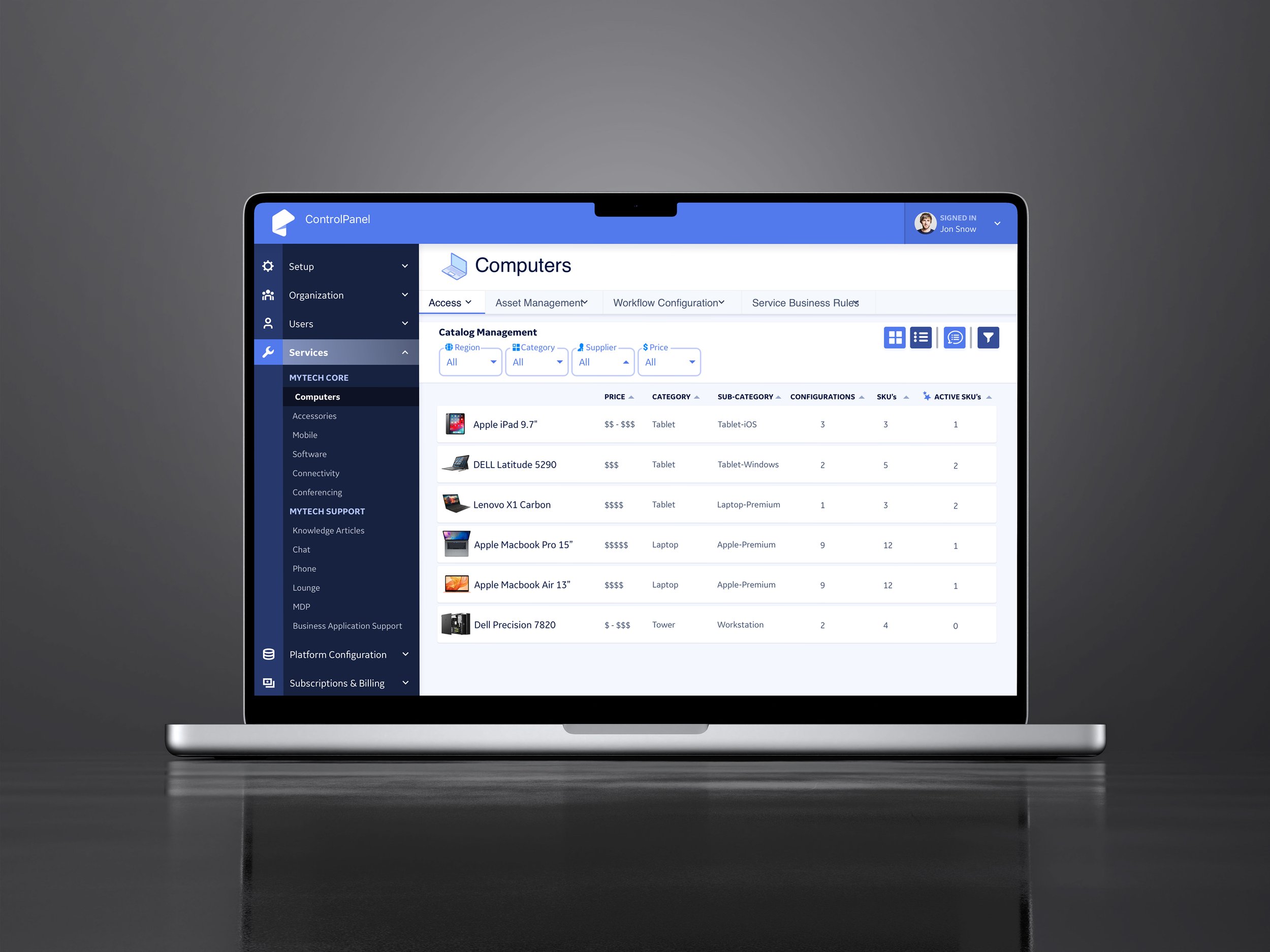

Computers selection page

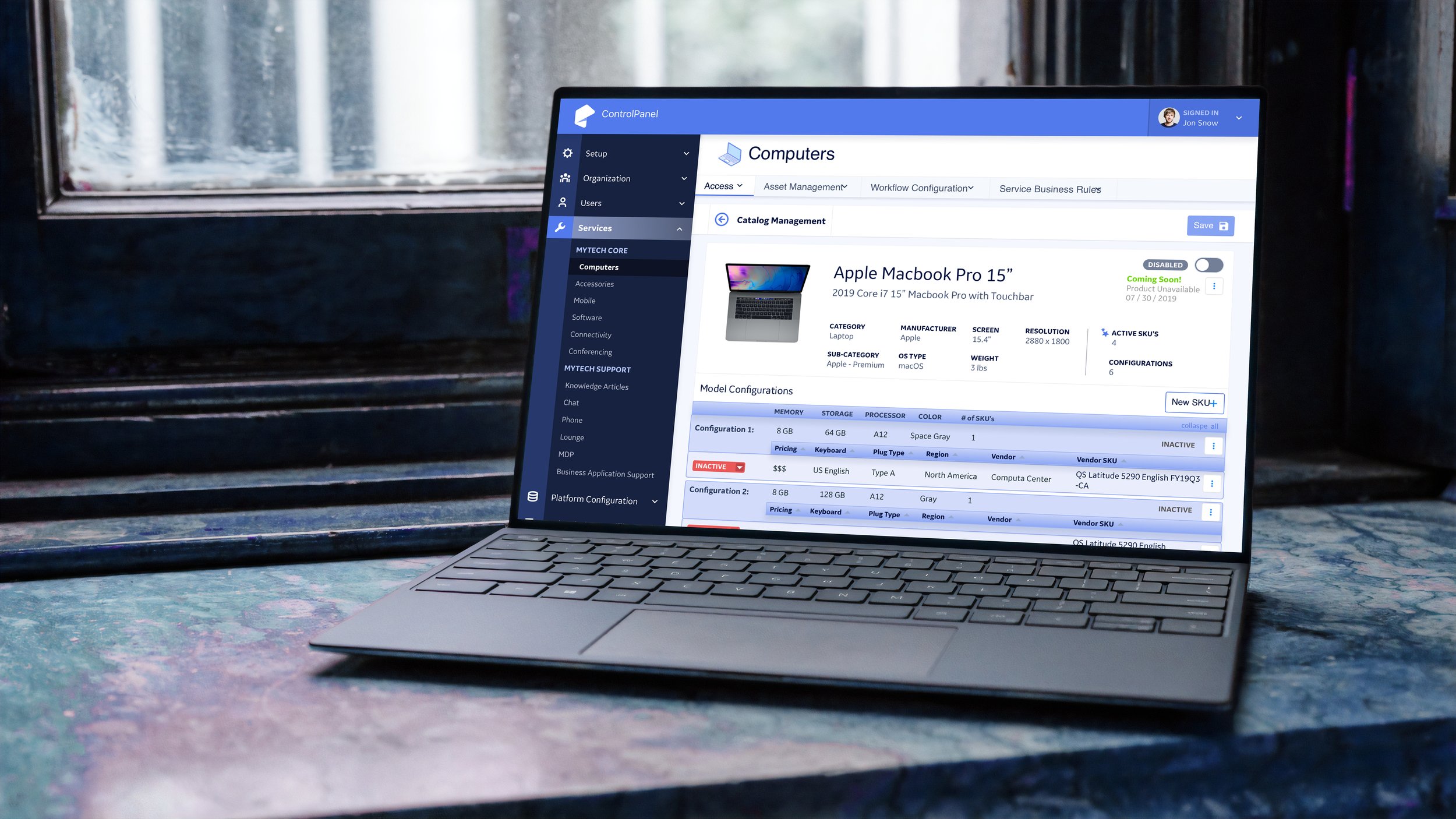

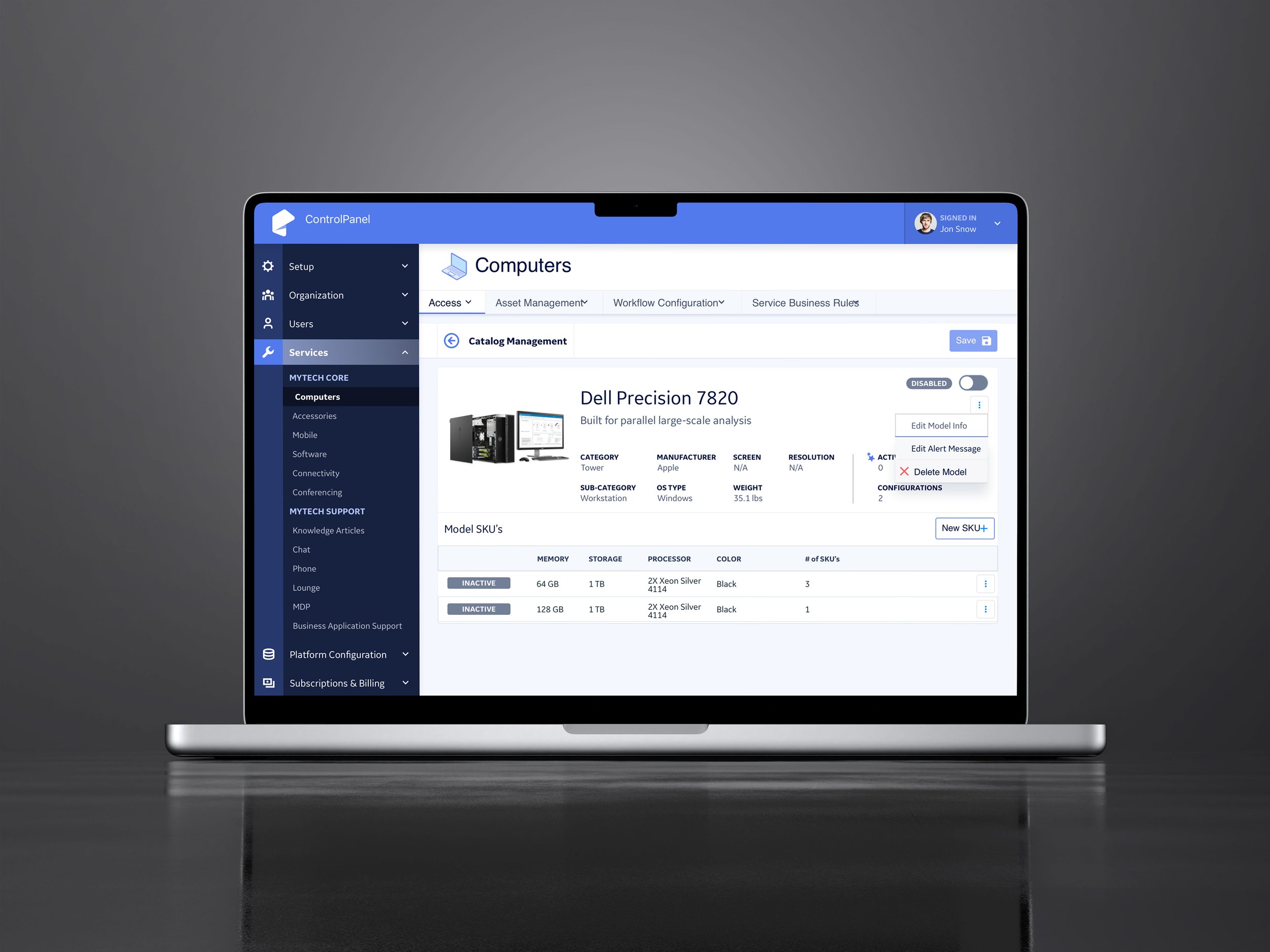

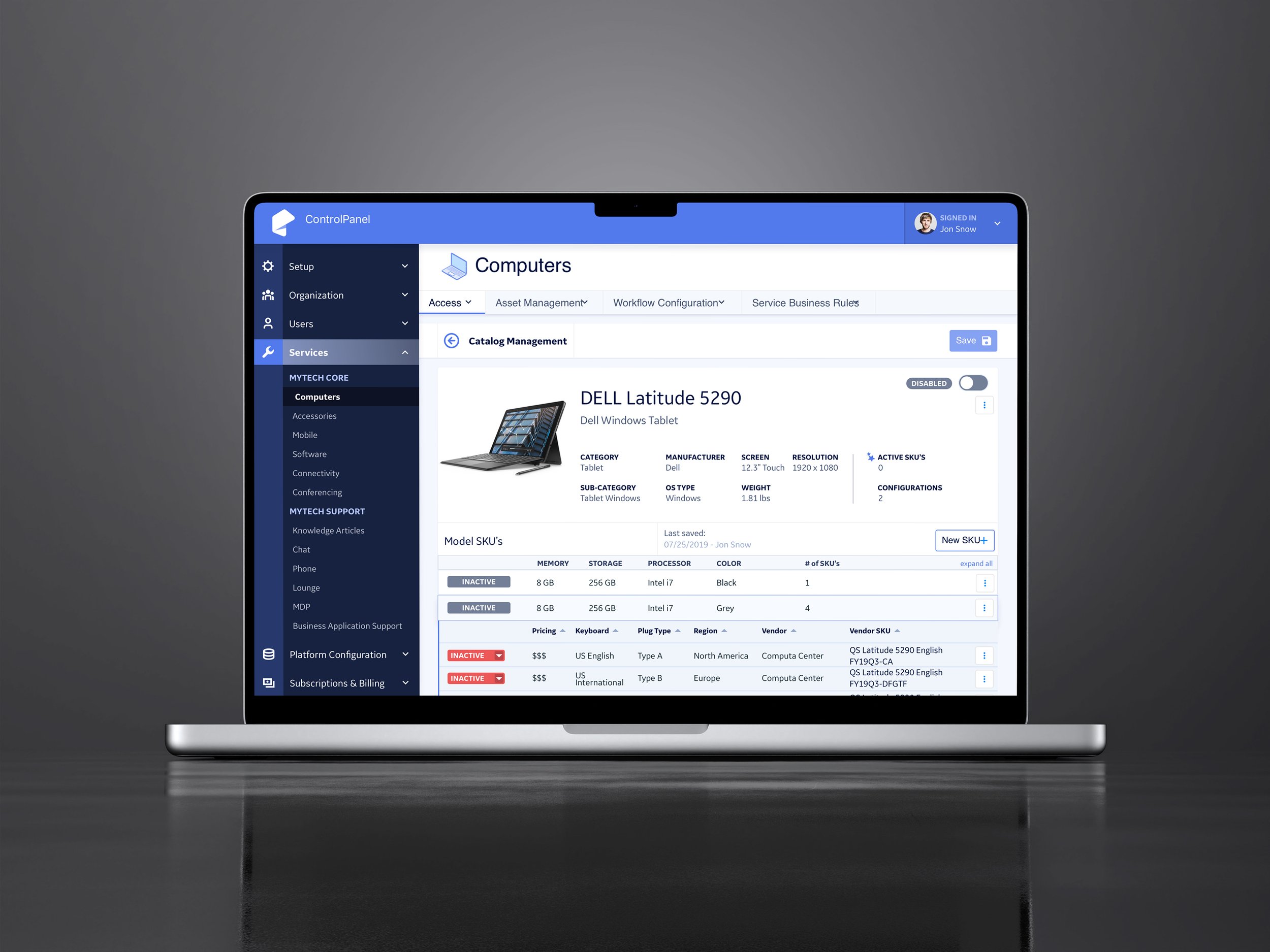

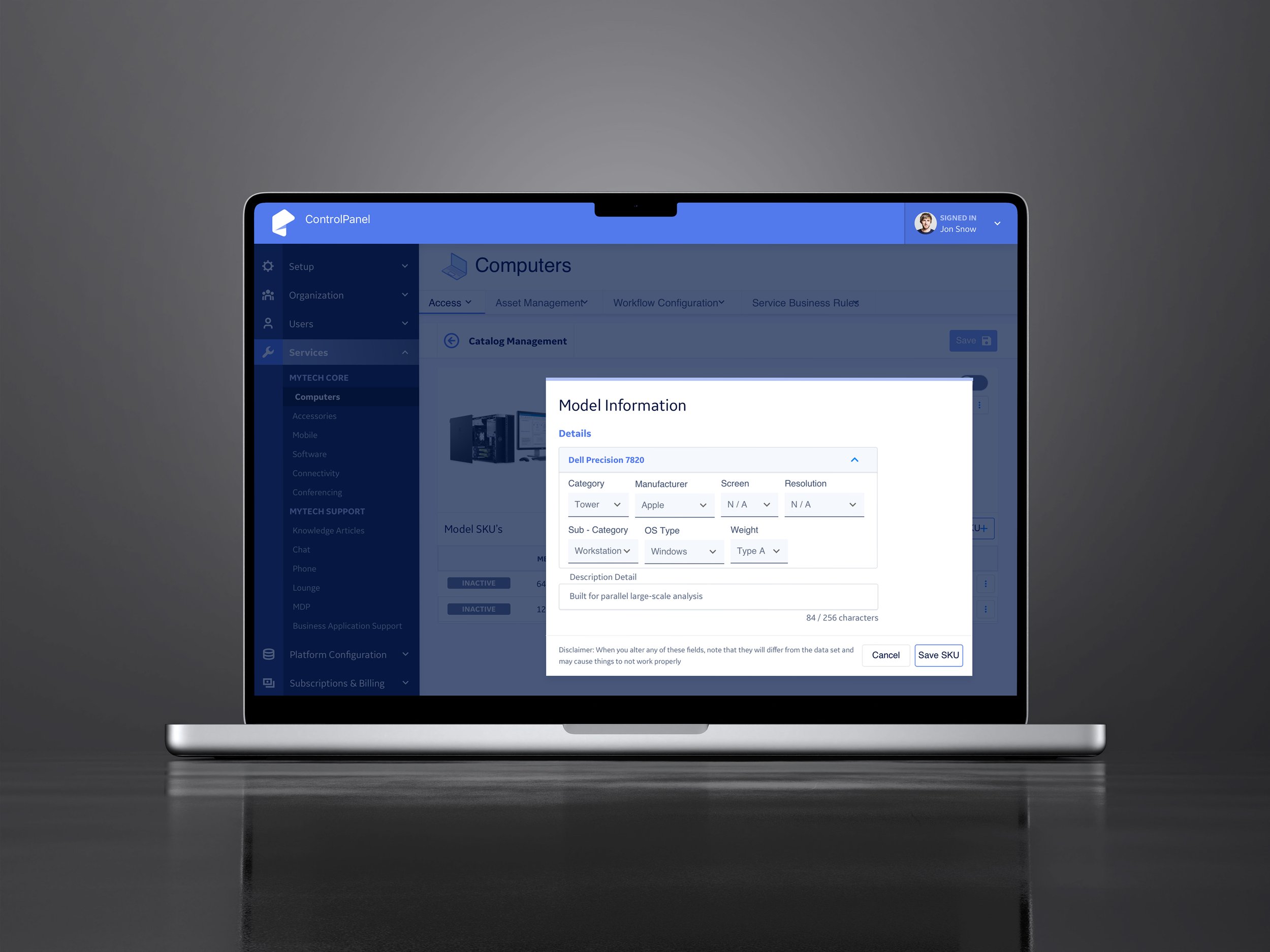

Computer selected with variants

Computer selected with variants

Computer selected with variants

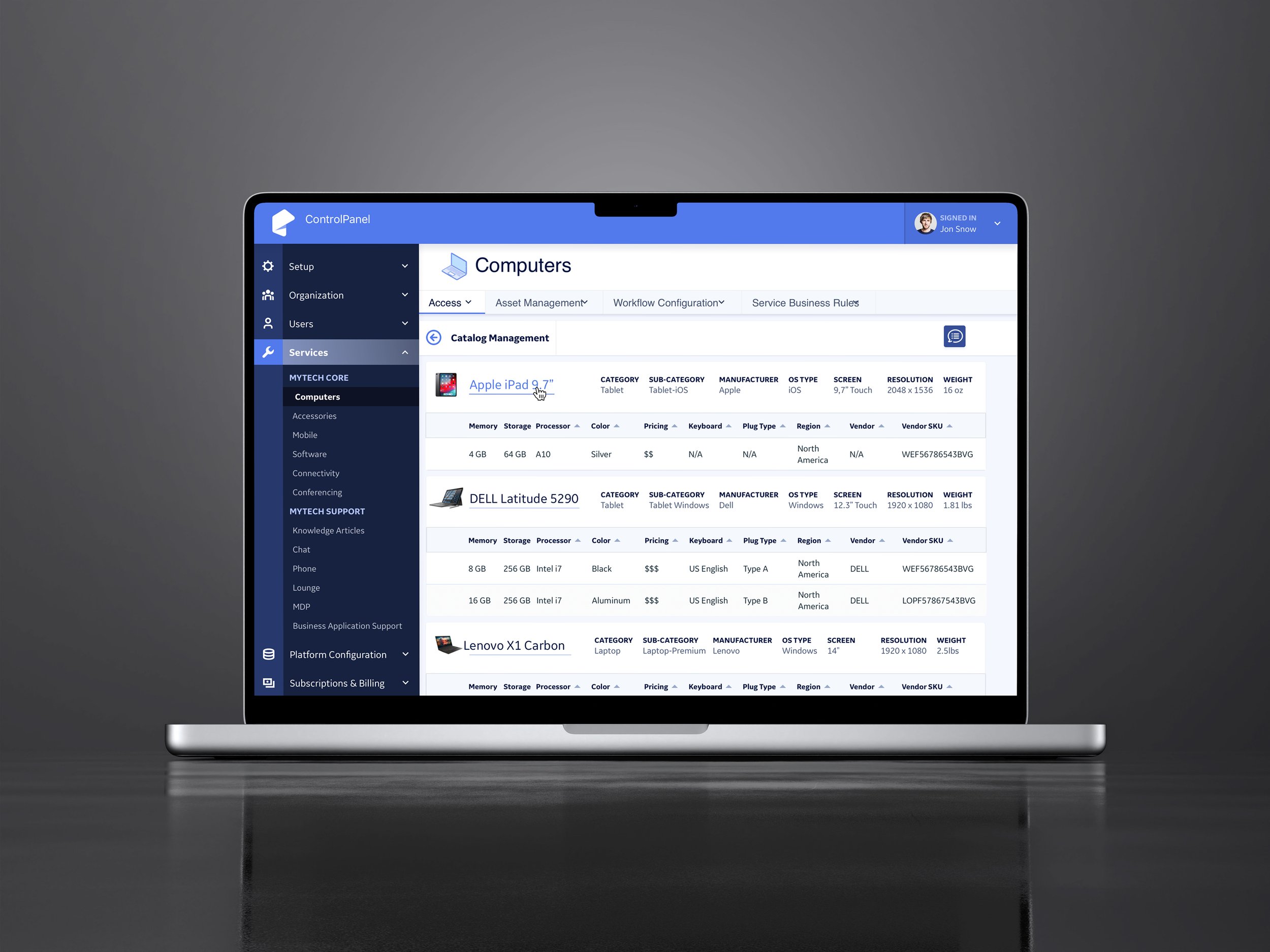

Alt view of computer selections

list view of computer selections

Creating logic rules

Integrating a data source

Configuring your asset

03

Bringing clarity to a dense enterprise workflow

Turning Complex Inventory Rules into Intuitive UI

Large-Scale Wireframing — Produced 500+ mid- and high-fidelity wireframes covering every edge case, from SKU browsing and procurement to admin setup, templates, and workflow logic.

Visual Hierarchy That Reduces Cognitive Load — Introduced a simplified, blue-based visual system with readable tables, scalable components, and clear action cues to minimize user stress.

Procurement & SKU Browsing UI — Designed catalog views with sortable grids, configurable filters, and data-rich SKU cards to help employees compare devices and understand requirements quickly.

Admin Control Panels — Built comprehensive layouts for managing data sources, configurations, entitlement rules, and template-based device groupings.

04

Delivering a complete build-ready package

Preparing GE with Everything Needed for Implementation

Full Workflow Coverage — Consolidated 500+ wireframes into clear, end-to-end flows covering ingestion, mapping, approvals, SKU browsing, and procurement.

High-Fidelity Screens — Produced detailed UI mockups for all major tasks, enabling engineering to understand behavior, data mapping, and layout structure.

Clear System Rules — Documented permission logic, category structures, device groupings, and approval pathways so teams could develop without ambiguity.

Build-Ready Specifications — Delivered a cohesive foundation GE’s engineering teams could move forward with, even as the project shifted in priority and didn’t reach production.